View:26407Time:12 Sep,2023

What is translucent concrete?

Translucent concrete is not really considered a new material.

The Hungarian architect Aron Losconzi invented LiTraCon (Light Transmitting Concrete) in 2001.

And, as early as at the Shanghai World Expo 2010

The Italian Pavilion, designed by Jim Paolo Imbrici

used light-transmitting concrete panels for the façade decoration

At that time, 3,374 pieces of light transmitting concrete panels were used

weighing 189 tons and covering an area of 1,887 square meters.

What exactly is it?

Translucent concrete is not exactly "transparent".

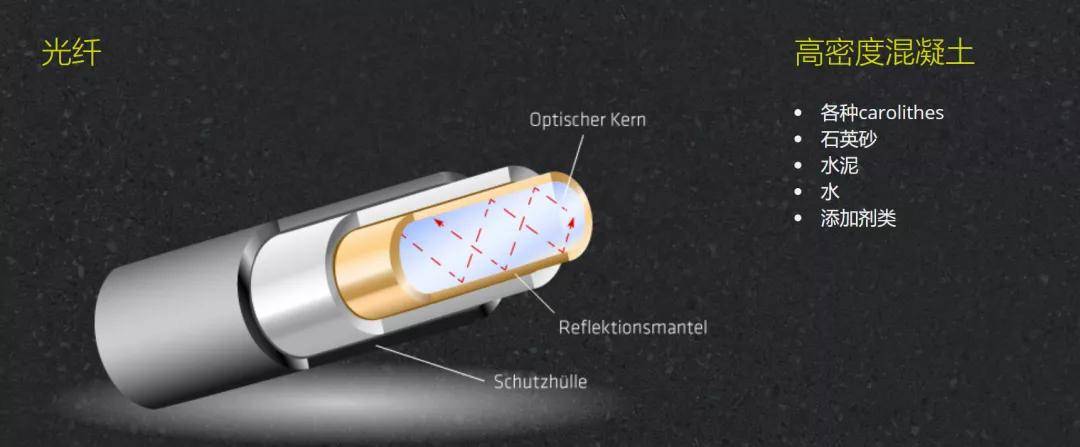

It is based on the interaction of three main components - concrete, fibers and light.

It relies on fiber optics to transmit light through the fiber while maintaining density.

It works by processing special glass fibers into the concrete.

by shining artificial or natural light on its surface

from one end to the other, which in turn makes it light-transmitting.

The fibers must therefore pass through the entire solid.

Sounds simple, but in reality it is very time-consuming

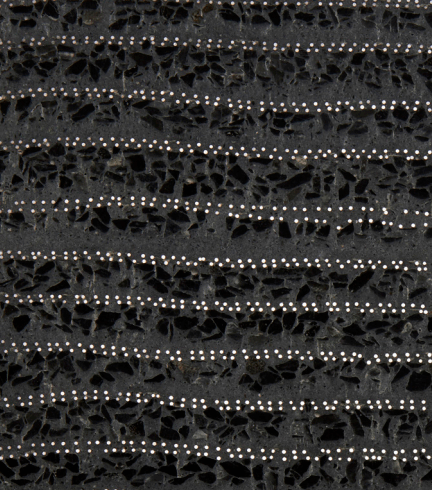

The fibers must be carefully inserted into the concrete by hand, layer by layer

and spreading it to match the final product

The entire process needs to be handmade to get the right results

Factors such as distribution, flow rate and ambient temperature can re-influence the results every time.

But this is what makes each piece of translucent concrete truly unique.

Fiber bundles that absorb and transmit natural and artificial light

Approximately 5% of the surface volume of light-transmitting concrete blocks

Tensile strength of approximately 70 MPascals

These fibers are mixed with conventional fine concrete (approximately 95%)

and evenly distributed over the entire surface

After setting, standard machinery for cutting stone is used to

The concrete is cut and delivered in the form of bricks, precast blocks or hanging panels.

What types and sizes of translucent concrete are available?

Currently, the common types of translucent concrete fall into three general categories:

Point Scatter, Linear Scatter, and Custom Scatter.

The colors are concrete natural color, black, white, etc..

The effects presented by these three categories are not the same, point and line for the fixed style.

The customized type can be customized with logo, slogan, etc., which is very stylized.

Al Aziz Mosque in Abu Dhabi, UAE.

The exterior wall is the use of customized style

Currently, the conventional thickness of translucent concrete is 20-50mm.

Conventional size: 1200*600mm, 1000*500mm, 500*500, 600*600, etc.

500*500, 600*600, etc. The rest of the sizes can be customized.

How does translucent concrete transmit light?

Depending on the degree of curvature of the fiber and the roughness of the fiber cut surface

Transmittance of light is usually slightly less than half of the incident light on the fiber

Given a five percent fiber, the final projection is about two percent.

But since the human eye responds to light in a non-linear fashion

so it can still provide useful light.

Theoretically, optical fibers can transmit light around corners and over distances of tens of meters

Rate of loss increases with length

The least amount of light is lost over a distance of about 20m

This depends on the type of fiber and how it is bent

Therefore, the material can be customized by choosing the density and diameter of the fiber

It is also possible to modify the transmittance (i.e. the amount of light) allowed by the material

When using natural light, it is important to ensure that there is enough light available

Wall-mounted systems need to be equipped with some form of lighting that

Designed to achieve uniform illumination over the entire surface of the panel

Usually a mounting system similar to that of natural stone is used.

With the resulting light-transmitting panel, the

viewer can clearly see the outline of the object on the other side of the concrete.

On top of this clarity, the

translucent concrete retains its strong, crack-resistant, load-bearing qualities.

For too long, concrete has been monotonous, dull and depressing.

associated with prison-like office buildings, ugly terraces and unfinished basements.

However, because of its light-transmitting properties

translucent concrete has the ability to transform the interior of concrete buildings

making them look fresh, open and spacious.

Applications of translucent concrete

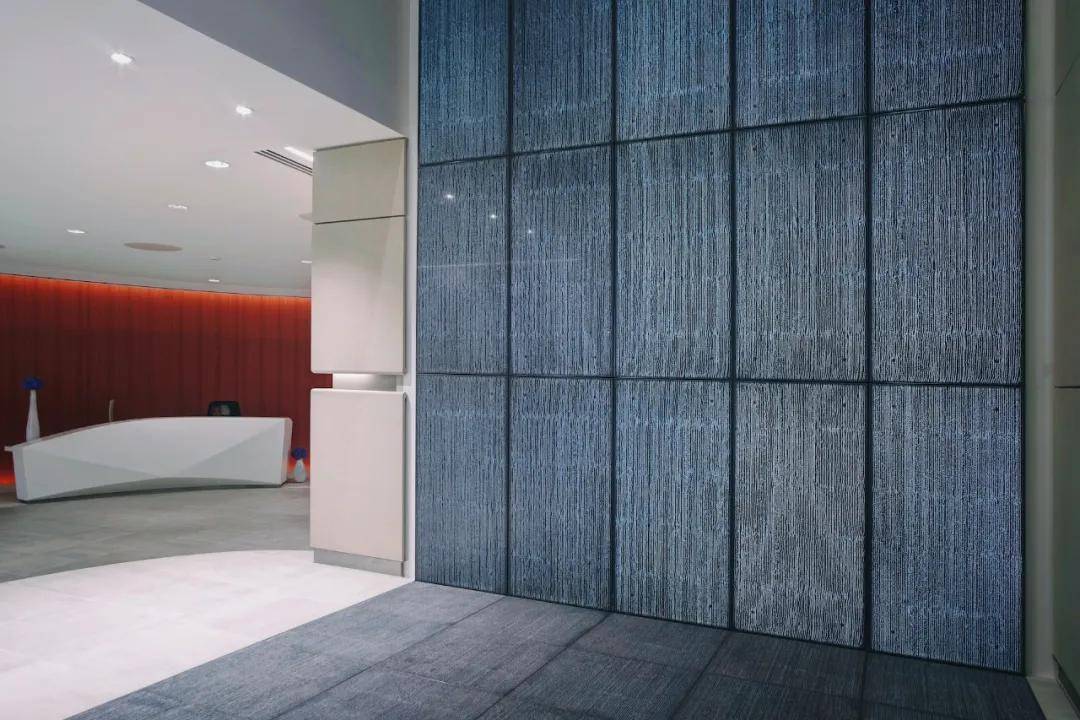

Since its development, translucent concrete has been widely used for architectural wall coverings

In a public square in Stockholm, Sweden

During the day, the square's sidewalks look as if they are made of ordinary concrete

But at night, when illuminated by colored lights under the surface

The translucent surface lights up

Meanwhile, in Eastern Europe, the newly renovated headquarters building of the Bank of Georgia

boasts nearly 300 square meters of light-transmitting concrete from a German manufacturer

including LED-lit wall panels.

All of the above highlights the use of translucent concrete in advanced buildings

As an exterior wall material and interior cladding

as an architectural and design tool

Transmits and diffuses daylight within a building to provide energy efficiency

as a structural and insulating element

to make buildings sustainable and private

But in fact, both indoors and outdoors

Translucent concrete can also provide suitable decoration in many places

1. it can be used for staircase decoration and it can serve the same purpose as decorative light strips;

2. can be cut into blocks and stacked in the form of bricks for decoration;

3. can be used on the ground, play a leading role as well as decorative effect;

4. can be customized lamps and lanterns, unique;

5. can even be customized for indoor and outdoor furniture, seating, table tops and so on.

If you have any demand for translucent concrete, please contact me through the contact form on the website.

Copyright © Shenzhen Miluo Industrial Co., Ltd all rights reserved.Support:FHCMS