The so-called architectural curtain wall, that is, the building's exterior wall enclosure, not load-bearing, like a curtain to hang up, it is also known as "curtain wall", is a modern large and high-rise buildings commonly used with a decorative effect of lightweight walls.

So there are several kinds of curtain wall materials?

First of all, the curtain wall on the market is mainly divided into three categories: stone, glass, metal. Just each material installation method has some differences, we focus on understanding the dry hanging process of stone curtain wall today. Mainly solve the following problems:

(1) what kinds of stone curtain wall dry hanging methods?

(2) How to dry hanging irregular broken collocation material? What are the characteristics and precautions?

First, the stone curtain wall dry hanging method

Stone curtain wall dry hanging methods are mainly 7 kinds: single-limbed short groove, double-limbed short groove, steel pin type, through the groove dry hanging method, small unit dry hanging method, back bolt type, pallet type. Several forms of curtain wall "short groove" and "back bolt" is the most common.

1, single-limb short groove dry hanging method

Single-limbed short slot is the adjacent two stone panels, common fixed in the "T" shaped card on the "T" shaped card for stainless steel or aluminum alloy, card and then fixed with the skeleton.

But now "T" shaped card strip has been eliminated, can only use "L" shaped card strip.

2、Double limb short groove dry hanging method

Double limbs short groove dry hanging method is a single limb short groove improvement practices, the same will be adjacent to the two stone panels are jointly fixed in the "dry" shaped card on the "dry" shaped card is generally extruded aluminum alloy, fixed with the skeleton.

3、Steel pin dry hanging method

Steel pin dry hanging method, also known as the pin method, is the earliest and most concise practice of dry hanging stone process, steel pin type is divided into two side connection and four side connection.

Structure is characterized by two adjacent stone panels fixed in the same steel pins, steel pins fixed in the connecting plate, connecting plate and then fixed with the skeleton.

4, the advantages of crumbling material dry hanging method

Through the slot hanging method generally use aluminum alloy SE combination pendant (part of the T-type or butterfly pendant), in each slab on the lower side of the opening of the long groove, groove depth of less than 15mm, the width of the groove should be 6mm, the thickness of the pendant is greater than 4mm.

5, the advantages of broken materials dry hanging method

Small unit type dry hanging method is by the metal sub-frame, a variety of single plate using metal hooks and columns, beams connected to the building can be dismantled curtain wall.

The stone in the small-unit dry-hanging process is connected to the skeleton through aluminum alloy clips, but the adjacent stones are independently connected to the skeleton (aluminum alloy beams).

This connection completely changed the traditional dry hanging stone curtain wall physical properties, design methods, processing methods and construction techniques.

6, the advantages of broken material dry hanging method

Back bolt dry hanging method is the stone panel and keel structure for connection, and then with the help of embedded parts will keel structure fixed in the building structure, at the same time with the help of the bottom of the top hole technology, the back bolt of the pendant and the stone panel for effective fixing.

This way can effectively avoid the two connections of the open seam problem, and weaken the stone panel on the keel structure of the reaction, to a large extent, to avoid the local destruction of the stone.

7, the advantages of crumbling material dry hanging method

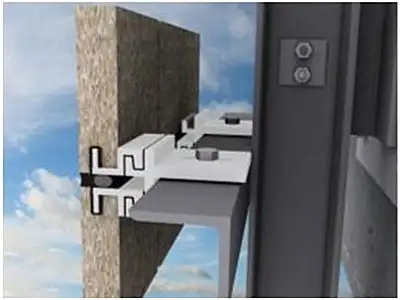

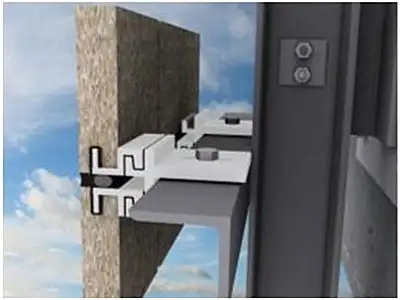

Pallet type connection form is the use of aluminum alloy pallet connection, bonding is completed in the factory, reliable quality.

Installation structure is using hanging structure, installation can be adjusted three-dimensionally. Installation using elastic rubber pads enables flexible connection and improves seismic performance.

The above seven ways are to metal pendant will finish stone hanging directly with the wall or empty hanging and steel frame, only suitable for solving the rules of the surface material, that irregular splinter material how to realize the curtain wall dry hanging?

Second, the irregular fragmented material dry hanging to realize the way

1、The advantages of dry-hanging of fragmented materials

(1) Drill holes in the original building structure to install expansion bolts, and then 5 angle steel fixed on the wall. According to the demand and mechanical calculation to determine its installation density and depth to form a steel skeleton.

2) Stamping 3~5mm galvanized thin steel plate into honeycomb plate, and determining the size and density of holes according to the actual situation on site. Generally according to the average size of irregular surface decorative materials to determine the minimum area of material, at least should cover more than 5 holes is appropriate to ensure the installation of irregular surface decorative materials firmness.

(3) On-site use of stainless steel drilling screws, galvanized honeycomb steel plate fixed in the welded steel skeleton, the use of flexible structural adhesive applied to the irregular surface layer of decorative materials. The position of the paste needs to be aligned and pressed down hard, to be part of the flexible structural adhesive from the galvanized honeycomb steel plate holes can be overflowed.

(4) irregular surface decorative materials installation is completed, to be flexible structural adhesive air-drying solidification, the use of drilling screws on the part of the irregular surface decorative materials for the second time to strengthen the surface holes produced by the use of color cement to repair.

(5) After color mixing, use the cement for embedding the gaps between the irregular surface decorative materials.

2、Points for attention of process

1)Safety considerations

Considering the possibility of shedding of curtain wall materials, it is necessary to test the adhesion of flexible structural adhesive and steel plate.

The use of grass-roots steel perforation to realize the overflow of glue into the hook method of hanging irregular curtain wall material technology, to ensure that the adhesion between the finish material and the steel plate.

(2) Anti-peeling treatment on the back

The use of multi-angle bevel cutting groove, so that the back of the material to form a concave groove, structural adhesive to fill the concave groove to form a torque hook form, to increase the structural adhesive and the bonding force of the irregular surface layer materials.

3)Deepening design adjustment of dry-hanging structural materials

The structural material is fixed on the base structure of the dry-hanging system of indoor and outdoor curtain wall of irregular material by the way of physical anchor bolt.

Considering the height of the indoor and outdoor curtain wall is too high, the area is too large, the self-weight of the single piece of surface layer decorative material is large, and the multi-panel layer is easy to cause the surface layer to be broken or peeling phenomenon.

Can be fixed by layering local surface hidden anchor bolt, the surface material and grass-roots steel anchoring, to prevent the surface material of the broken and sagging.

3、Advantages of dry-hanging of broken materials

(1) Solve the installation difficulties of various irregular fragmented materials curtain wall.

(2) Improvement of safety: Ultra-thin metal plate is used as the grass-roots level, which reduces the self-weight of the structure and the influence on the grass-roots level, and combined with the triple stabilizing technology, it prevents the surface material from crushing and sagging.

3)Improvement of economic efficiency: the surface material is inexpensive, not easy to wear and tear, light weight, low freight costs, and later maintenance is simpler than that of natural stone.