View:9123Time:30 May,2025

Terrazzo was invented by construction workers in Venice, Italy in the early 20th century. They used superb manual labor to expose marble fragments on the finished surface of concrete. It was unique in style and popular for a time. It was introduced to China in the late 1950s and used in large buildings such as schools, airports, and hospitals. Due to the limitations of the production process at the time, terrazzo itself also had disadvantages such as troublesome care, easy penetration, easy wear, and easy weathering. After the 1990s, new materials began to appear. The performance and price of granite and artificial stone were more advantageous than traditional terrazzo, and terrazzo was gradually forgotten.

In recent years, with the rise of retro trends and the development of technology, terrazzo has reappeared in front of people. However, the current terrazzo is no longer the rough appearance of the past, but has evolved into a fashion expert and a symbol of a new style, successfully counterattacking.

Terrazzo has begun to appear in various characteristic buildings, fashion spaces, luxury stores, and even furniture and decorations. Moreover, not only the terrazzo industry itself, but also artificial stone, ceramics, wallpaper and other industries have begun to imitate the color style of terrazzo and compete to help it.

The origin of terrazzo

The origin of terrazzo can be traced back to Venice in the 16th century. Craftsmen took the marble and scraps left over from the decoration of luxury houses back home and inlaid them in the yard at will. After simple treatment, unexpected effects were obtained. Therefore, the English name of terrazzo, Terrazzo, originated from the Italian word Terrace.

In addition, the Italians also found that applying goat milk on the surface of terrazzo would greatly improve the glossiness. Therefore, applying goat milk became the earliest and most primitive polishing method. Later, it was migrated to the United States and other countries by Italians. In the late Qing Dynasty, terrazzo technology crossed the ocean and came to China.

The development and changes of terrazzo

In the impression of most Chinese people, terrazzo is probably just a simple and stereotyped "gray memory" in classrooms and hospital corridors. Its low price, wear resistance, and easy construction make traditional terrazzo a standard decoration in the 1970s and 1980s.

Traditional terrazzo has a huge market in China with its unique advantages such as low cost, arbitrary color matching and easy construction. In the 1980s, no one had the concept of "decoration". Everything was mainly to meet practical functions. The ground was mostly bare cement. The interior of a more advanced space would be paved with terrazzo. At that time, the terrazzo floor was generally polished by adding white granular marble to cement.

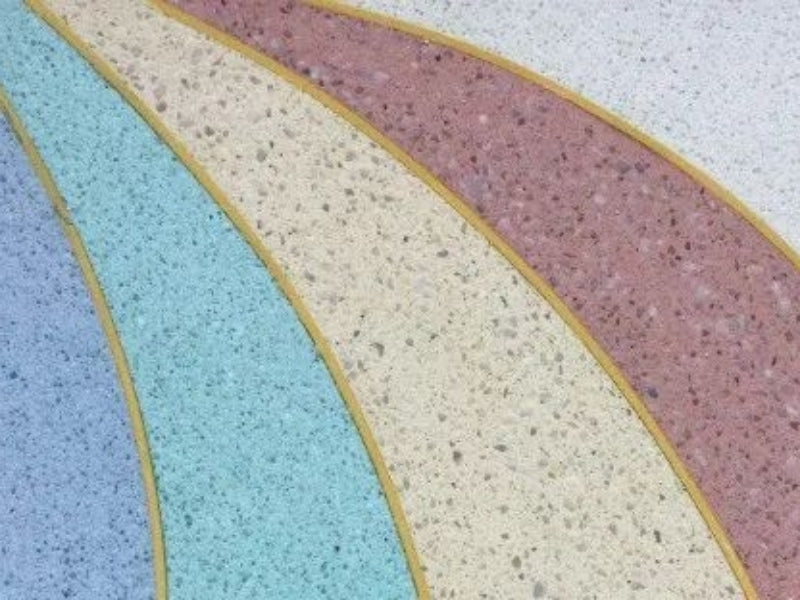

The colorful use of terrazzo

With the enrichment of materials and the advancement of manufacturing technology, terrazzo presents richer colors and patterns. Under the creative application and matching of designers, whether it is the delicate material of terrazzo or its texture, it has become the darling of the decoration industry with its random and colorful shapes and has stepped onto the international stage. It can be found in commercial spaces, residential homes, furniture, accessories, lamps and other industries.

This terrazzo is so fashionable that you can't recognize it

What is terrazzo?

Although terrazzo looks like a whole piece of dotted texture, it has irregular stone patterns with dots in the pattern, which has an uncertain random beauty and presents a sense of "similarities". After artificial design, the products are not only very rich, but also varied, making it a well-deserved favorite of fashion.

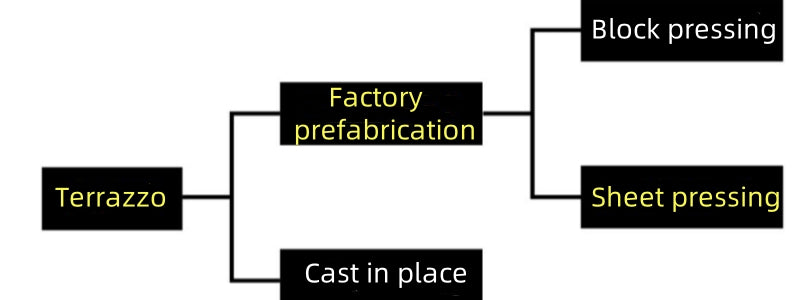

Traditional terrazzo is a product made by mixing aggregates such as crushed stone, glass, and quartz stone into cement binder to make concrete products, and then grinding and polishing the surface. There are generally two types of on-site cast floors and factory prefabricated panels, and each has its own characteristics:

On-site casting (terrazzo floor) has a long history and is constructed by skilled workers. It has high technical requirements for construction workers. One area is formed at one time (if the area is too large, it is divided into multiple areas). The same area can achieve no seams and no obvious color difference, and the overall appearance is very atmospheric and beautiful.

Advantages

1. Seamless splicing, atmospheric and beautiful, and the mosaic effect is shocking;

2. Super large area is formed at one time, and there is no obvious color difference in a single area.

Disadvantages

1. Manual operation, the precision is difficult to compare with precision equipment;

2. Without high-frequency vibration and high-pressure pressing, the physical properties are limited;

3. Self-leveling molding, manual polishing, the surface flatness is wavy;

4. The construction conditions are demanding and cross-operation is prohibited;

5. After construction, regional protection is required, which affects the overall construction period;

6. The wall cannot be applied.

Problems

1. The bonding strength is not enough, and the aggregate is prone to loosening and falling off;

2. The water absorption rate is high and it is easy to be penetrated by stains;

3. The density and strength are not enough, and cracking is easy to occur;

4. Later damage is difficult to repair.

Factory prefabricated type

Factory prefabricated terrazzo is processed by modern equipment in the factory. It generally goes through processes such as fabrication, vibration, high pressure, maintenance, and cutting. It has high controllability. The finished product is a single sheet, which is convenient to transport and mature in construction. The construction method is similar to that of tiles and marble, and is suitable for application in various environments.

Advantages

Produced by precision equipment, stable quality, uniform performance, high density, high strength, water absorption rate must be controlled at a low level. Production line, batch replication, higher efficiency, convenient transportation and storage, convenient construction, efficient cross-operation, small impact, conducive to ensuring the overall construction period, can be applied to walls, stairs, and even countertops, flexible application, and more convenient later maintenance and replacement

Disadvantages

1. High loss, obvious seams in paving;

2. Color difference is prone to occur in multiple batches of products.

Problems

1. Black seams are prone to appear at the joints;

2. Paving construction requires specifications, otherwise hollowing and cracking are prone to occur.

If you are looking for decorative panels for both indoor and outdoor use, Mosaic terrazzo is the perfect choice. Producing in one environment will make any area where it is installed more visually appealing. As long as you are careful and properly maintained, stones can remain beautiful for many years. Click here for details; Mosaic terrazzo More style information.

Copyright © Shenzhen Miluo Industrial Co., Ltd all rights reserved.Support:FHCMS