View:3598Time:08 Sep,2023

Requirements for Building Foundations

1.1 Decorative concrete panels are installed after applying a thin mortar cement on the building walls to ensure accurate positioning and prevent irregularities or warping that could affect the appearance of the floating effect. Installing them after plastering can also prevent damage to and contamination of the precast concrete panels that have already been installed.

1.2 Before installing decorative concrete panels, the base surface should undergo appropriate chiseling and waterproofing treatment to avoid hidden issues after installation.

1.3 During the installation of decorative concrete panels, secure and safe scaffolding is required. The scaffolding should be positioned at least 300mm away from the wall and not smaller than the dimensions of the concrete decorative panels projecting outward to facilitate construction and installation.

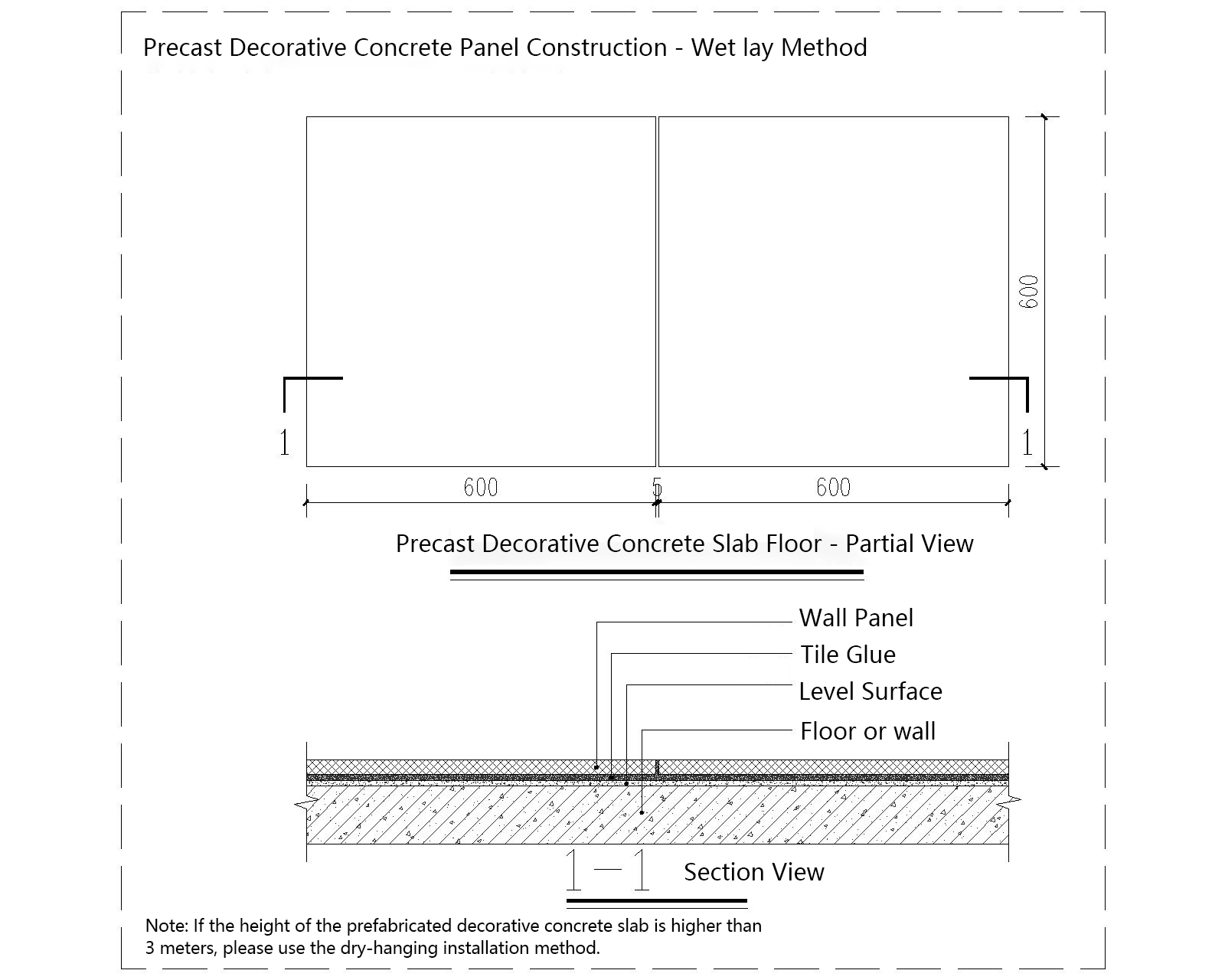

Decorative Concrete Panel Installation Methods Decorative concrete panels can be installed using wet adhesion or dry hanging methods. Dry hanging installation includes side-groove dry hanging, back-groove dry hanging, and back-anchored dry hanging methods.

Wet Adhesion Installation Requirements (see Figure One for details) In general, wet adhesion is used for floors, and dry hanging is used for walls. If the wall does not meet the dry hanging requirements and is below 3 meters in height, decorative panels with dimensions within 1200*600* 20mm can be installed using the wet adhesion method. The thickness of the floor wet-adhesion panels should be between 30mm and 50mm.

3.1 Check the Floor's Flatness Check if the floor to be laid is flat enough. If the floor is uneven, it may need to be leveled with a shovel, and in severe cases, re-leveling may be necessary.

3.2 Check the Floor's Moisture Content

Measure the moisture content of the floor using a moisture meter. The standard requirement for ordinary floors is <20%. Excessive moisture content in the floor can cause the decorative concrete panels to absorb water and expand, leading to issues such as warping, bulging, and noise on the panel's surface. Therefore, if the floor's moisture content exceeds the standard value, dehumidification should be performed before installation.

3.3 Check the Floor's Stability

You can tap the floor with a hammer to check for hollow sounds or peeling. If such issues exist, the floor should be treated and properly prepared before laying the panels.

3.4 Check for Adequate Waterproofing Measures

Prefabricated decorative concrete panels are susceptible to water infiltration, which can lead to alkalinity and deformation, rendering them unusable. Therefore, before installation, it's crucial to inspect the waterproofing measures and address any water leakage issues inside the house, if present, before proceeding with the installation.

4.Dry Hanging Installation Requirements

The thickness of the panel should be between 20mm and 30mm. If the panel is larger, a 50mm edge should be folded on all four sides.

Preparation Work:

4.1 Before installing the components, specific alignment and positioning must be carried out as follows:

4.1.1 Draw lines on the installation base to mark the installation positions, including horizontal and vertical lines. The allowable error range for horizontal alignment should be within 3mm.

4.1.2 The positioning of the installation must be accurate. Check the flatness and verticality of the installation base. If the error exceeds ±2mm per 1000mm, it should be controlled during component installation.

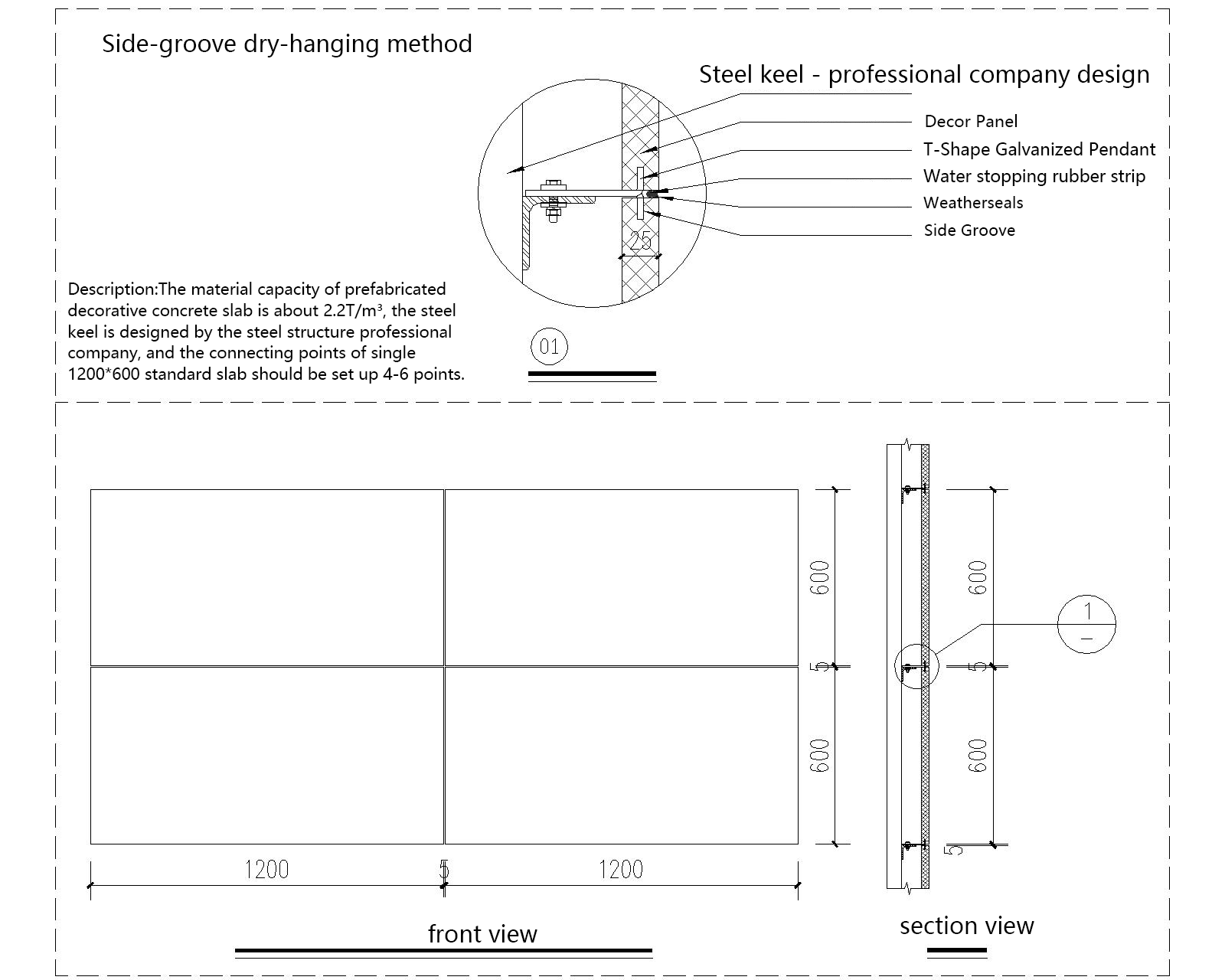

4.2 Side-Groove Dry Hanging Method

The decorative concrete panel is grooved on both sides of the front face. T-shaped galvanized hangers are connected to steel joists, and before installation, they are bonded to one panel using waterproof adhesive tape. The other hanging panel is then tightly installed in place. The material density is approximately 2.2T/m³, and there should be 4-6 connection points for each 1200*600 standard panel.

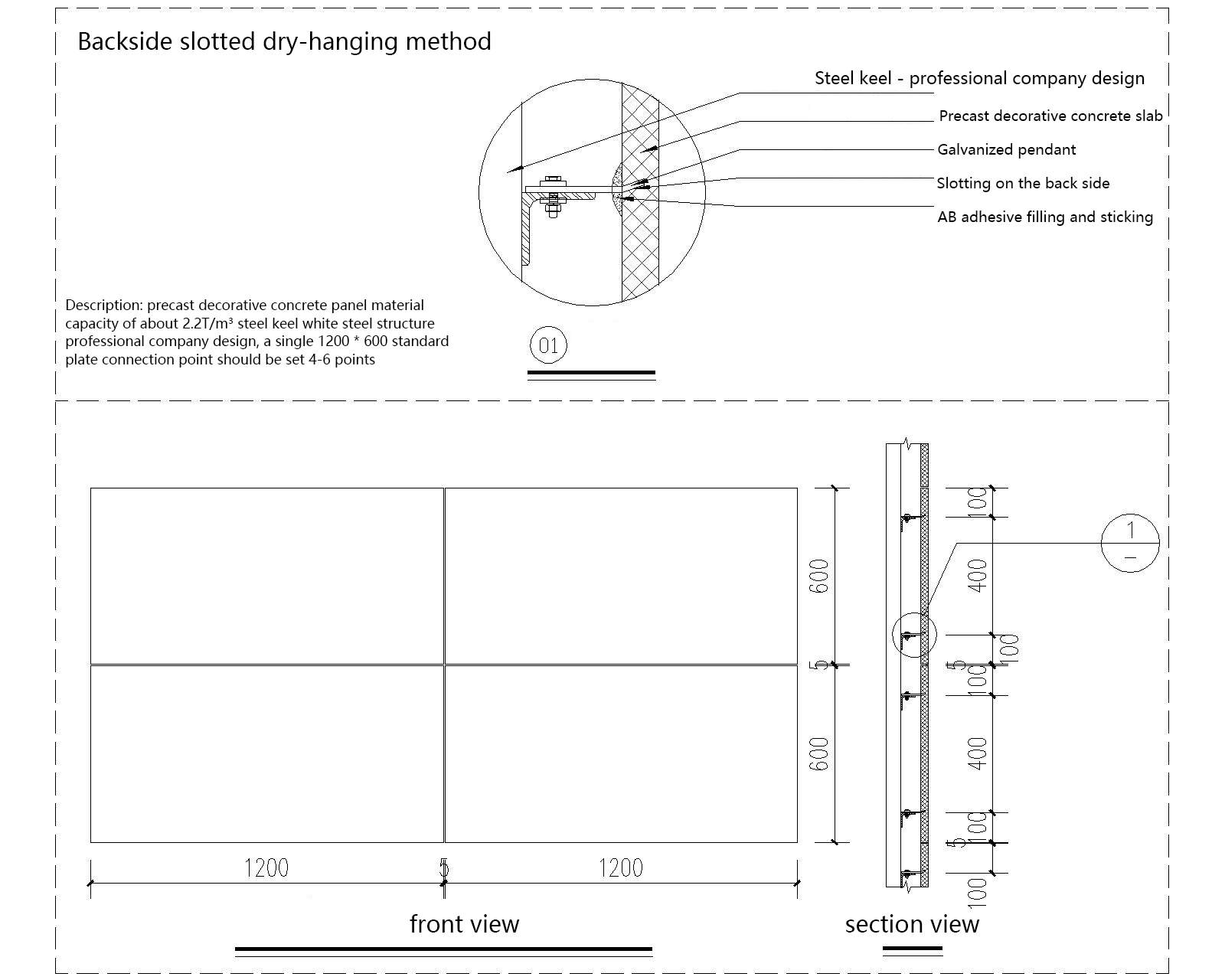

4.3 Back-Groove Dry Hanging Method

In the back-groove dry hanging method for decorative concrete panels, grooves are made on the back of the panels. Galvanized hangers are connected using AB adhesive, and then steel joists are attached during installation. Before installation, waterproof adhesive tape is applied to one panel, and the other hanging panel is tightly installed in place. The material density is approximately 2.2T/m³, and there should be 4-6 connection points for each 1200*600 standard panel.

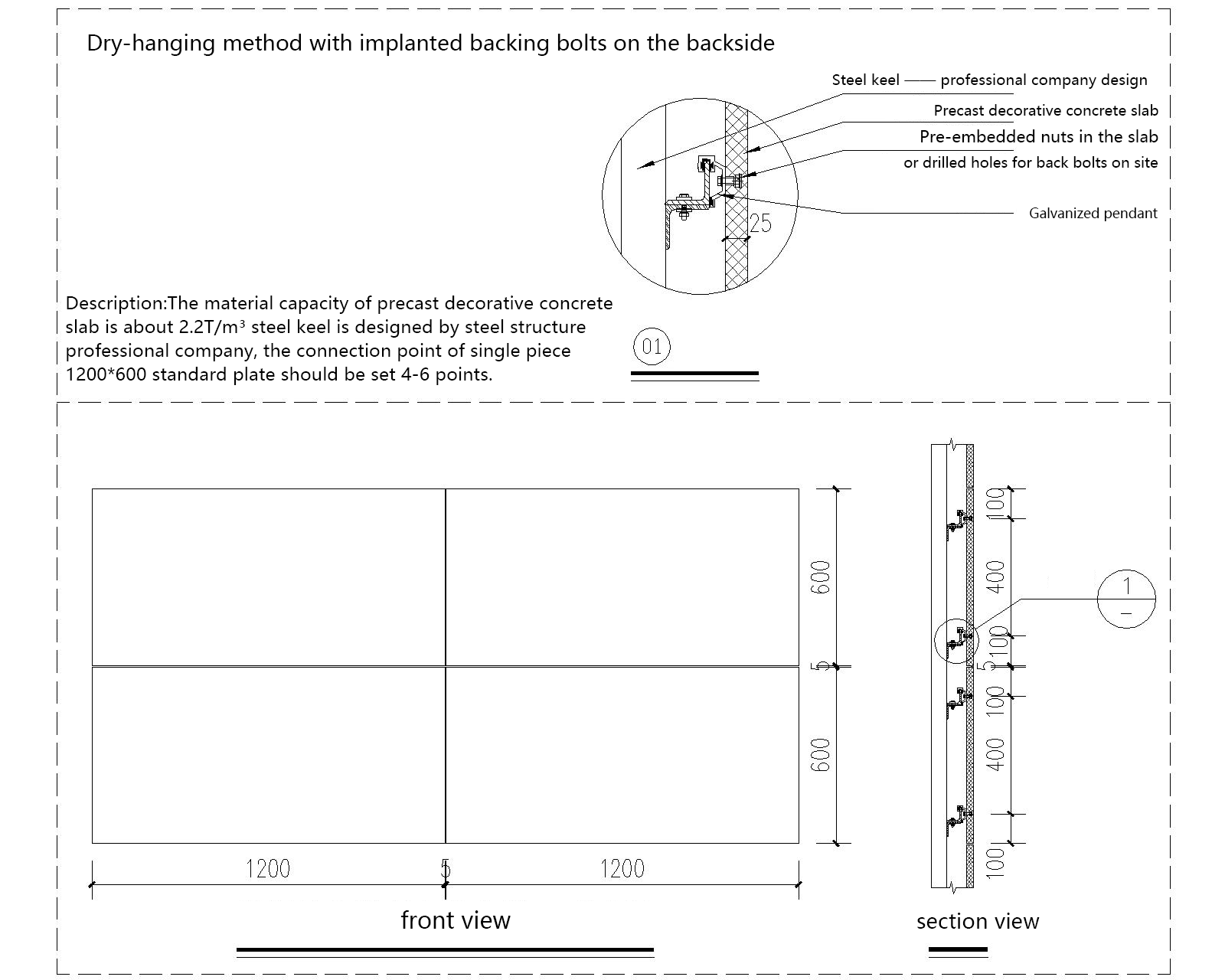

4.4 Back-Bolted Dry Hanging Method

In the production process of decorative concrete panels, nuts are embedded inside the panel or anchor bolts are inserted on-site and connected to steel joists. Before installation, they are bonded to one panel using waterproof adhesive tape. The other hanging panel is then tightly installed in place. The material density is approximately 2.2T/m³, and there should be 4-6 connection points for each 1200*600 standard panel.

5.Joint Treatment

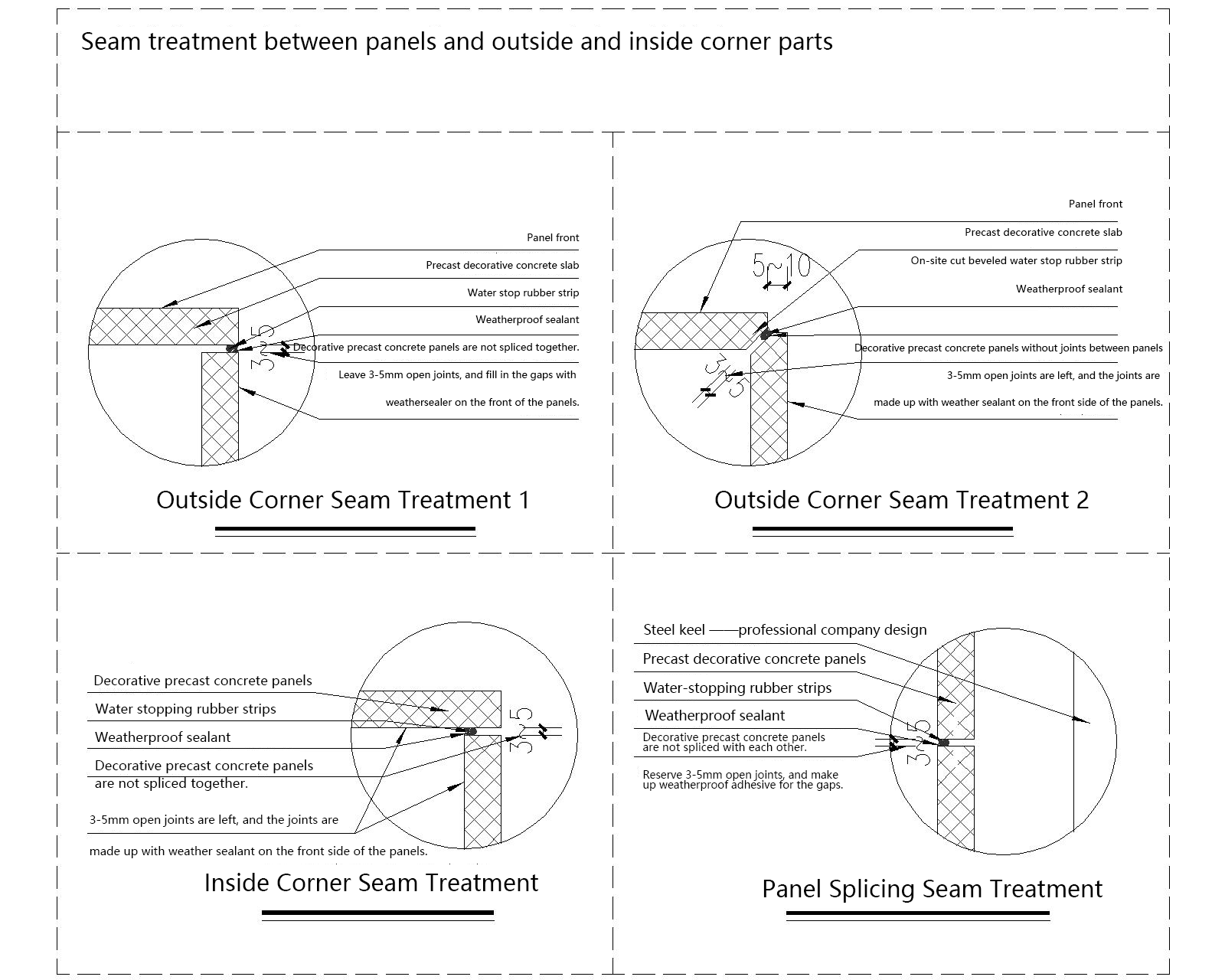

After the installation of decorative concrete hanging panels, it is necessary to address the panel joints, as outlined in various treatment options in Figure Five.

5.1 The joints of decorative concrete hanging panels should not be filled with cement, as this can create rigid constraints leading to deformation and cracks.

5.2 The treatment of joints in decorative concrete hanging panels should involve first aligning the joints, removing loose particles, and then applying weather-resistant sealant.

5.3 When applying sealant, the joints should not be wet, and work should not be carried out in rainy or snowy weather.

5.4 The sealant in the joints should be applied evenly, with a consistent depth and a smooth finish.

5.5 Both sides of the sealant joints should be covered with tape to prevent contamination.

5.6 For horizontal surfaces with drip features, a drip level should also be incorporated into the joint sealant to prevent rainwater from causing stains and contamination.

Copyright © Shenzhen Miluo Industrial Co., Ltd all rights reserved.Support:FHCMS